Core Technologies of the Micro Robotics Industry

The LIGA process refers to a technology that uses UV or X-Ray to process nanometer (nm) and micrometer (um) sized precision molds.

Numerous micro components and micro modules based on the LIGA process are currently utilized in the medical surgical robotics and micro robotics industries.

At WANTS we are focusing on the development of next-generation technologies that link innovation with innovation, as well as the development of applied technologies that utilize the LIGA Process.

LIGA Process

We are now able to manufacture more detailed parts through co-working. Below is our LIGA Process.

-

mandrel

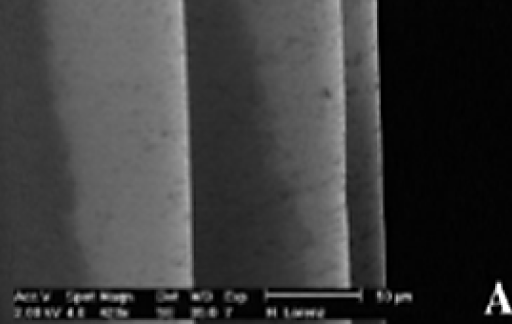

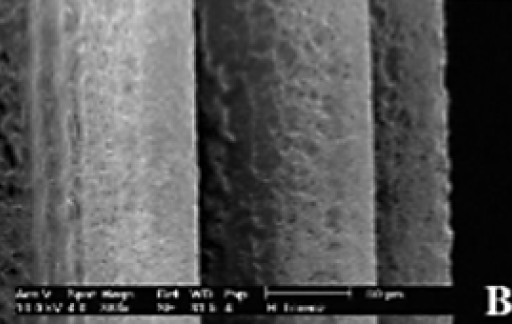

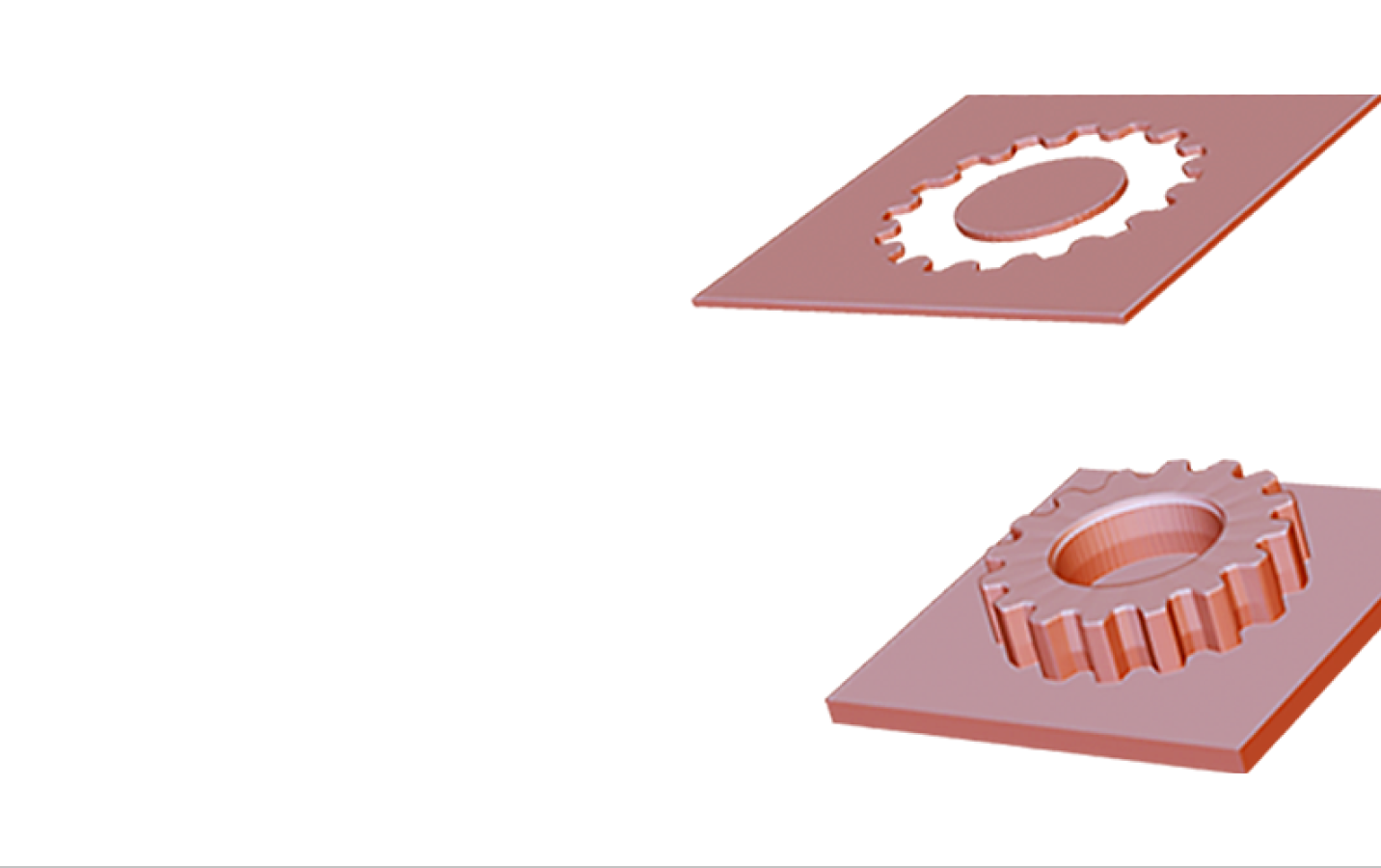

Production stage of a mandrel, a circular model made for the final process

-

Electro Forming

Electroforming, a stage in the fabrication of mold models from which parts are extracted

-

Remove Mandrel

The stage of removing the mandrel, the first circular model

-

Metal Mold

Completed mold model for injecting final parts

-

Micro 3D Modeling

The most important element in the micrometer-scale 3D structural modeling co-work process is communication.

The elaboration of the 3D modeling of the parts to be made in the end result follows, i.e., to the quality of the final part.

The first phase of Co-work begins through modeling to develop the mandrel.

-

X-Ray / UV Lithography

The core fixture of the LIGA process rests on X-Ray/UV Lithography technology for mandrel fabrication. Synchrotron and synchrotron radiation with excellent parallelism are pulsed light sources whose intensity is tens of thousands of times stronger than conventional light sources and have a continuous energy spectrum, enabling the realization of structures with high width ratios.

Synchrotron radiation is the best X-Ray light source for LIGA Process.

-

Electroforming

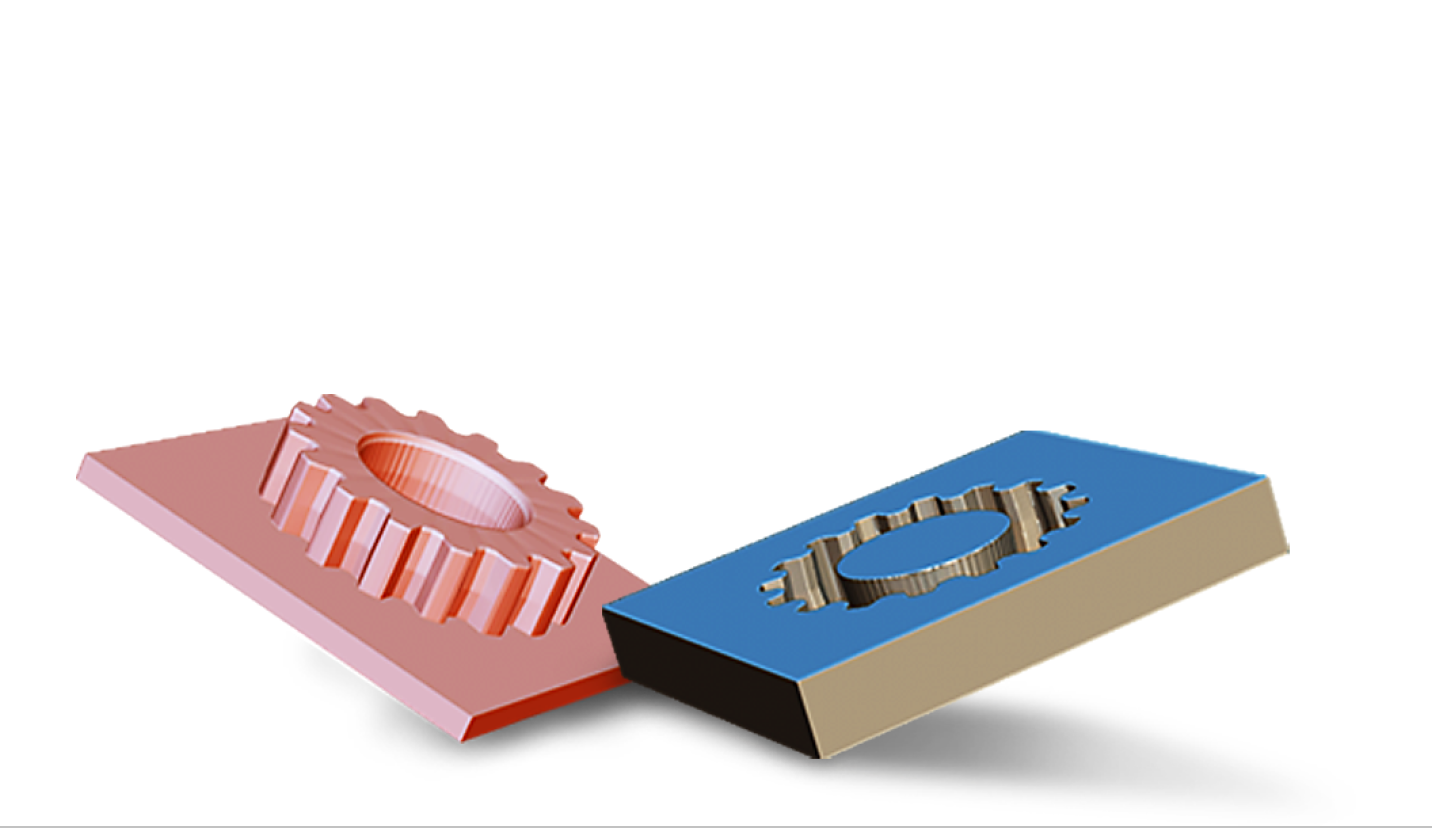

Through the completed micro mandrel, the final result of LIGA Process will be a micro mold model formed through Electroforming, an electroforming casting process.

X-Ray / UV Lithography

-

-

Micro Metal Mold

Completion of micro-mold model After removing the first mandrel, the injection molding process begins with the completed micro-metal mold.

-

Powder / Debinding

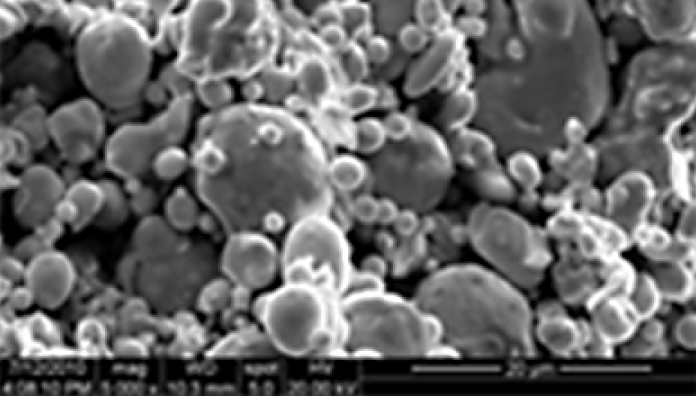

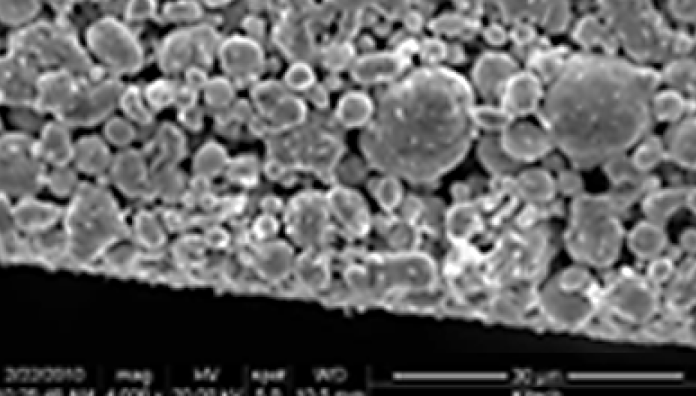

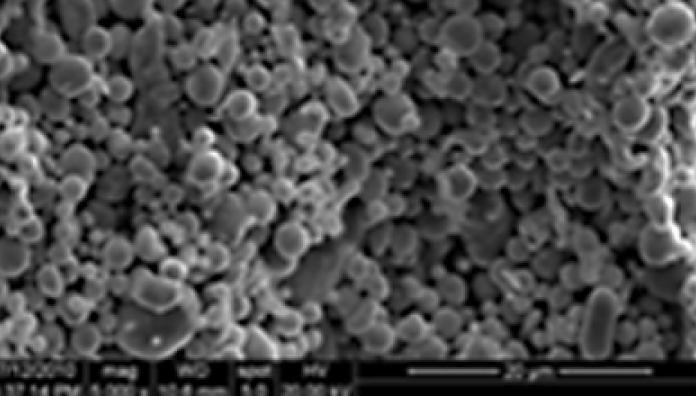

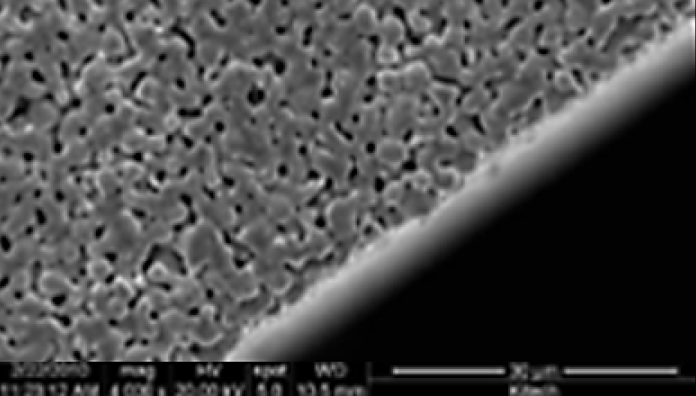

Micrometer- and nanometer-sized component densities are ultimately bound by the amount of the metal powder.

You can see the difference between 8um size metal powder and 4㎛ size metal powder.

8㎛ feedstock

4㎛ feedstock

-