Innovative technology for cost and quality

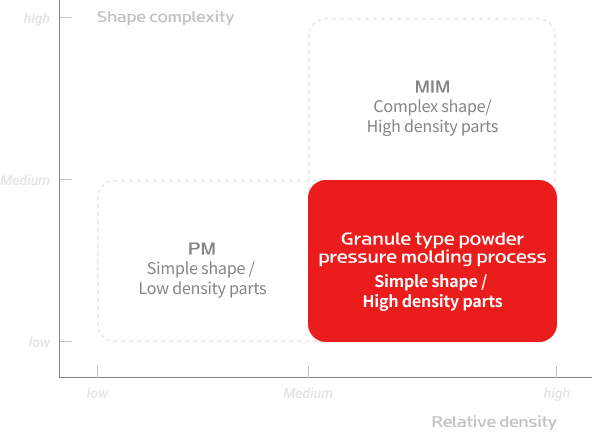

This is a method of manufacturing parts that combines the advantages of powder metallurgy and powder injection molding technologies.

The powder metallurgy method is characterized by simplicity of shape and high economy, the powder injection molding method is characterized by difficult shape realization and high density, but relatively high cost.

The micro-PM method of our company has the advantage of being able to offer high density products at an economical cost.

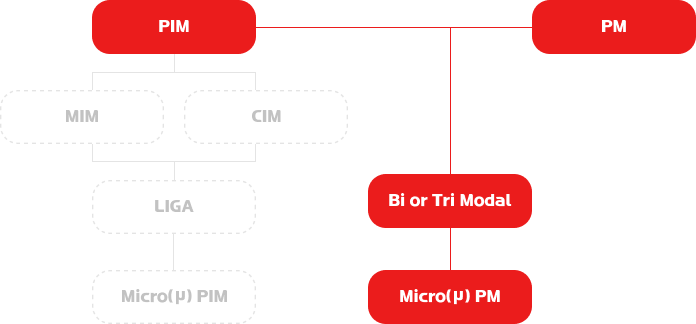

Micro PM Tech-tree

Combining powder metallurgy and injection molding, this is the most economical technology, using only the best advantages.

Micro PM Process

-

Mandrel

Production stage of a mandrel, a circular model made of the final part

-

Molding

Injection molding stage to process 'Green Part' parts

-

De-Binding

Brown Part stage in the process of degreasing the binder of injection molded parts.

-

Sintering

Post-processing progresses as needed at the Sintered Part stage, the final metal part.

-

Inspection

Final inspection stage to check for defects before shipping parts

-

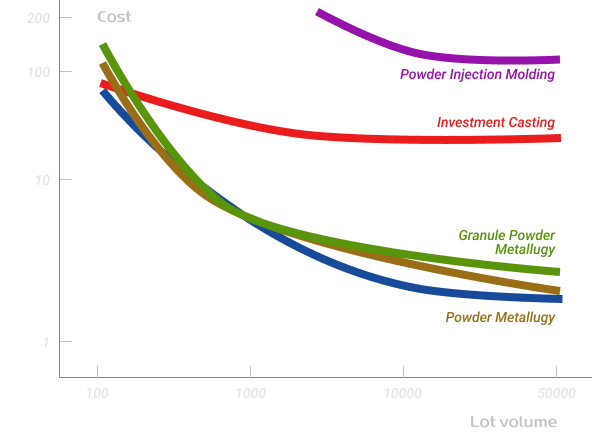

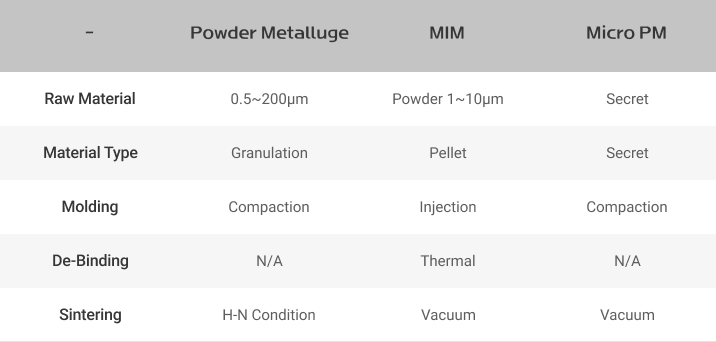

Compare another Technology

Compare with other Technology

-

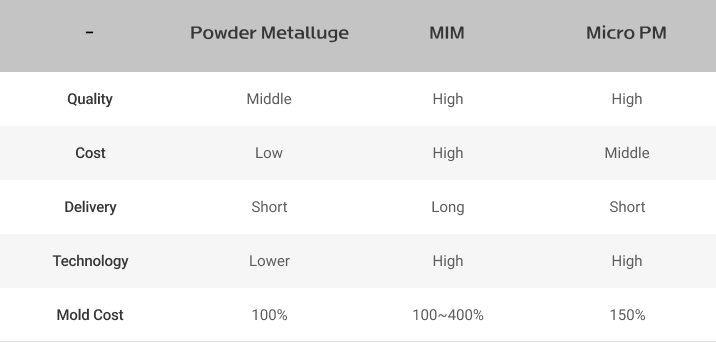

Compare QCDT

QCDT

-

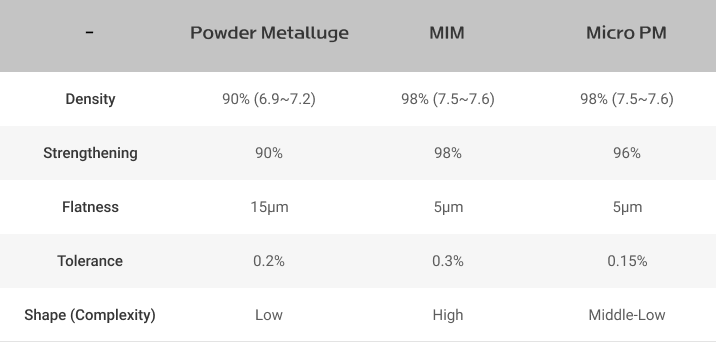

Properties

Properties